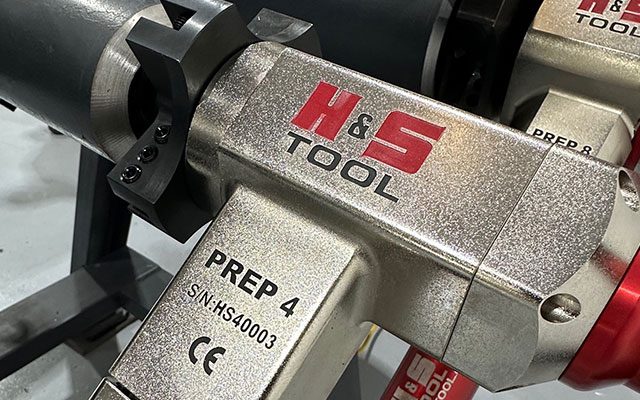

The H&S TOOL PREP 4 Pipe Beveler is a versatile and powerful ID locking, in-line feed end prep machine that excels in external and internal beveling, facing, counterboring, weld removal, and J-prepping, including tube plate facing. Compatible with any type of steel or exotic alloy, it can be mounted on straight pipes, elbows, and fittings for precise pipe prep and tube prep work. Available in pneumatic, electric, or battery (110V or 220V) power options, its exceptional power-to-weight ratio makes it unrivaled in its class. The 4-jaw tool holder accommodates up to four insert or form tools, allowing for simultaneous external, internal, and tube-facing tasks, ensuring accurate, repeatable results. Compact and robust, the PREP 4 is a popular choice for high-volume boiler repair, tube facing, and weld removal applications.

For rental inquiries, also check out the BG44 BOILER GUN