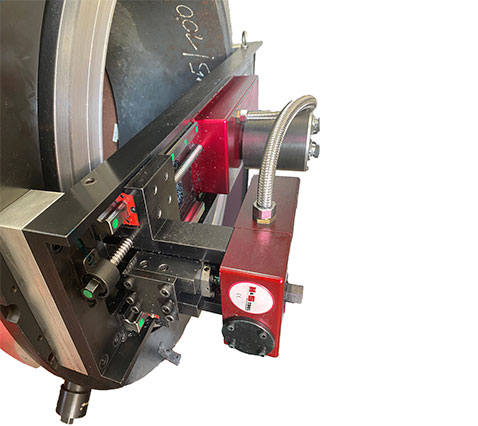

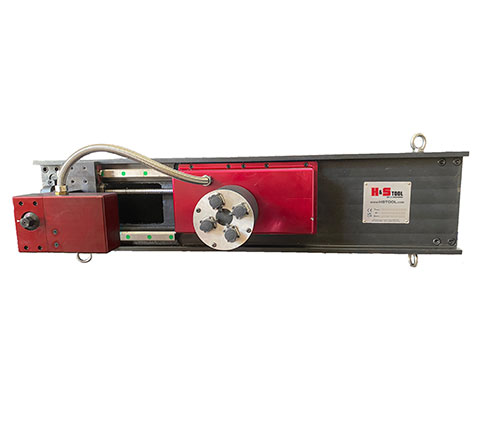

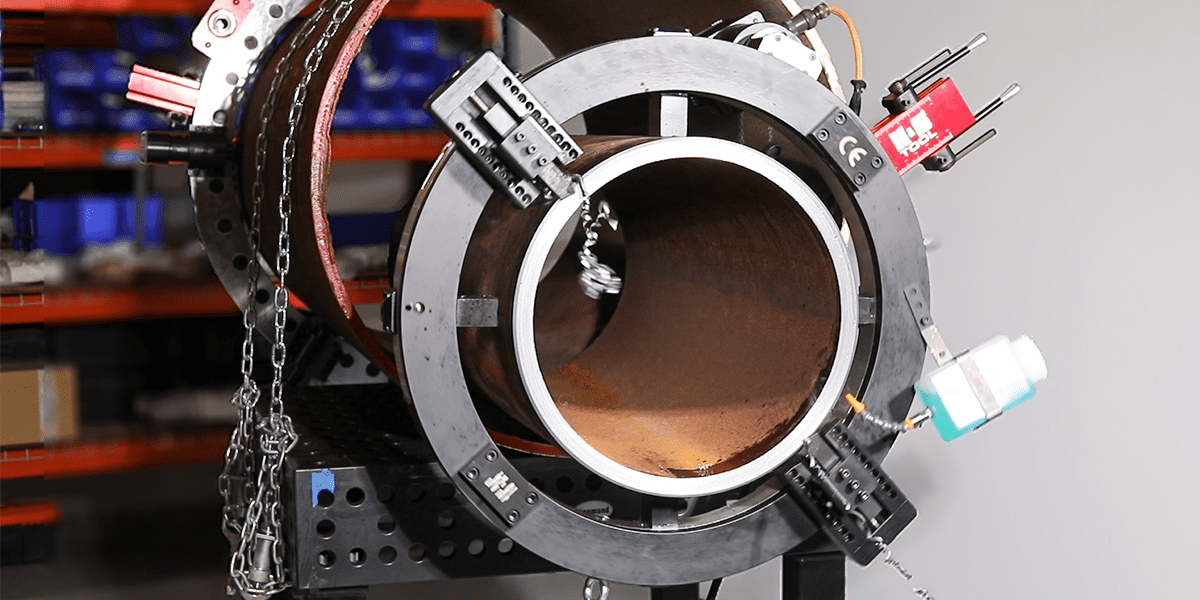

The H&S TOOL Split Frame Clamshell CNC Crossbar combines advanced CNC precision with unmatched versatility. Engineered for external and internal beveling, counter-boring, weld removal, flange preparation, OD turning, and more, it delivers consistent results on steel, exotic alloys, and titanium. With a user-friendly touchscreen control and seamless integration with HSSFC-series clamshells, operators can achieve complex, high-quality machining in a single setup—saving time, improving accuracy, and reducing costs.

Split Frame Clamshell CNC Crossbar

RANGE: 6.6" ID up to 76" OD / 168 ID up to 1,930 mm OD

Mobile Nav

| Part No. | Description | Working Range ID min to OD max | Split-Frame Part No. | Range (OD) | Controller Kit Part No. |

| HSCNCCB20 | H&S CNC Controlled Cross Bar for HSSFC20 | 168 – 470 mm / 6.6 – 18.5” | HSSFC20R | 355,6 – 508 mm / 14 – 20” | HSCNCCDE16-3P |

| HSCNCCB24 | H&S CNC Controlled Cross Bar for HSSFC24 | 273 – 590 mm / 10.7 – 23.2″ | HSSFC24R | 457.2 – 609.6 mm / 18 – 24” | HSCNCCDE16-3P |

| HSCNCCB30 | H&S CNC Controlled Cross Bar for HSSFC30 | 457 – 780 mm / 18 – 30.7” | HSSFC30R | 609.6 – 762 mm / 24 – 30” | HSCNCCDE25-3P |

| HSCNCCB36 | H&S CNC Controlled Cross Bar for HSSFC36 | 610 – 925 mm / 24 – 36.4” | HSSFC36R | 762 – 914.4 mm / 30 – 36” | HSCNCCDE25-3P |

| HSCNCCB42 | H&S CNC Controlled Cross Bar for HSSFC42 | 762 – 1,080 mm / 30 – 42.5” | HSSFC42R | 914.4 – 1,067 mm / 36 – 42” | HSCNCCDE25-3P |

| HSCNCCB48 | H&S CNC Controlled Cross Bar for HSSFC48 | 914 – 1,240 mm / 36 – 48.8” | HSSFC48R | 1,067 – 1,219 mm / 42 – 48” | HSCNCCDE25-3P |

| HSCNCCB60 | H&SCNC Controlled Cross Bar for HSSFC60 | 1,219 – 1,535 mm / 48 – 60.4” | HSSFC60R | 1,220 – 1,524 mm / 48 – 60” | HSCNCCDE25-3P |

| HSCNCCB75 | H&S CNC Controlled Cross Bar for HSSFC75 | 1,600 – 1,930 mm / 63 – 76” | HSSFC75R | 1,524 – 1,910 mm / 60 – 75” | HSCNCCDE25-3P |

H&S TOOL Split Frame Clamshell CNC Crossbar

1. Unmatched Machining Versatility

-

Performs a wide range of machining operations in a single setup:

-

External V- and J-beveling

-

Internal beveling

-

Counter-boring

-

Compound beveling

-

Weld removal

-

Flange facing and preparation (flat face, raised face, RTJ groove, male & female)

-

Norsok compact flange machining

-

OD turning

-

Radius preparation

-

Heat exchanger seal face machining

-

-

Reduces the need for multiple tools, saving time and improving efficiency.

2. Superior Material Capability

-

Designed to machine all types of steel, exotic alloys, titanium, and other hard materials.

-

Built to handle the most demanding applications in nuclear, offshore, oil & gas, and power generation industries.

3. Advanced CNC Precision

-

Features a fully programmable single-point CNC Crossbar for extreme accuracy.

-

Dual brushless motors control the interpolating X and Z axes, ensuring precise tool trajectory and accurate joint preparation.

-

Guarantees consistent, repeatable, high-quality results.

4. User-Friendly CNC Control

-

Operated through a 7” wired touchscreen remote pad with intuitive, license-free software.

-

Operators can fully customize cutting parameters (rotation speed, feed rate, depth of cut, etc.).

-

Offers full control before and during machining operations for maximum flexibility.

5. Efficient Setup and Operation

-

Seamlessly integrates with the H&S TOOL HSSFC-series Split Frame Clamshells.

-

Allows both cutting and CNC preparation within the same setup, reducing downtime.

-

Plug-and-play controller design makes setup straightforward and fast.

6. Scalable and Compatible System

-

Compatible across a wide range of clamshell sizes.

-

Offers the flexibility to adapt to small, medium, and large-scale machining requirements.

7. Dedicated Tool Holders and Inserts

-

Available outside and inside beveling tool holders provide flexibility for different applications.

-

Inserts for carbon steel and stainless steel ensure durability and adaptability.

8. Proven in Demanding Applications

-

Successfully deployed in critical nuclear applications for double-sided J-groove joint preparation with internal machining.

-

Demonstrated reliability, precision, and compliance with rigorous industry standards.

The H&S TOOL Split Frame Clamshell CNC Crossbar delivers unmatched precision, versatility, and efficiency for advanced machining operations. With robust CNC control, compatibility across clamshell sizes, and proven performance on the toughest materials, it empowers operators to achieve superior results with reduced time and cost.

BROCHURE

OPERATING MANUAL

Related Products