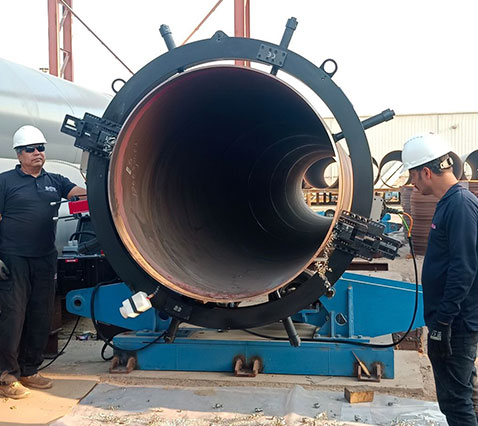

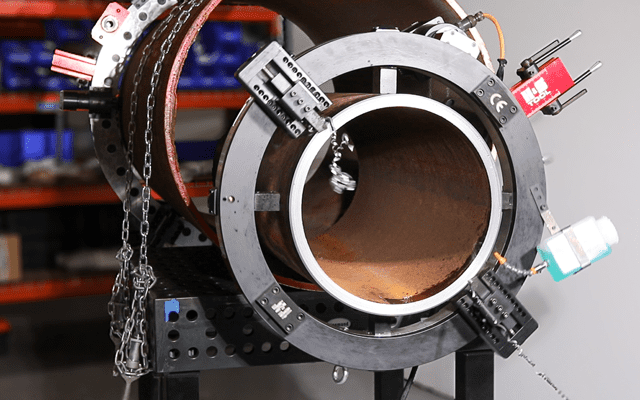

H&S TOOL’s new split-frame clamshells are essentially portable lathes. Offering the versatility to cut and bevel (simultaneously if required), face, counterbore, and OD machine pipes (and vessels) of almost any diameter. A steel body encases a steel inner ring gear, running on solid bearings. Coupled with wide, hardened clamping feet, with easy-read rule marks, enables rapid, repeatable concentric setup, even on out-of-round pipes and joints. A range of tooling, power units, and accessories allows you to tailor your machine to your particular job.

Larger sizes and customized machines available upon request