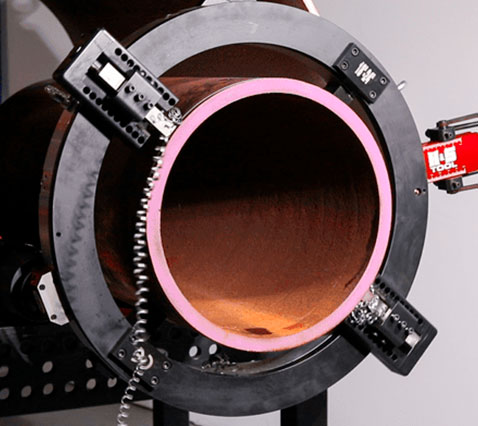

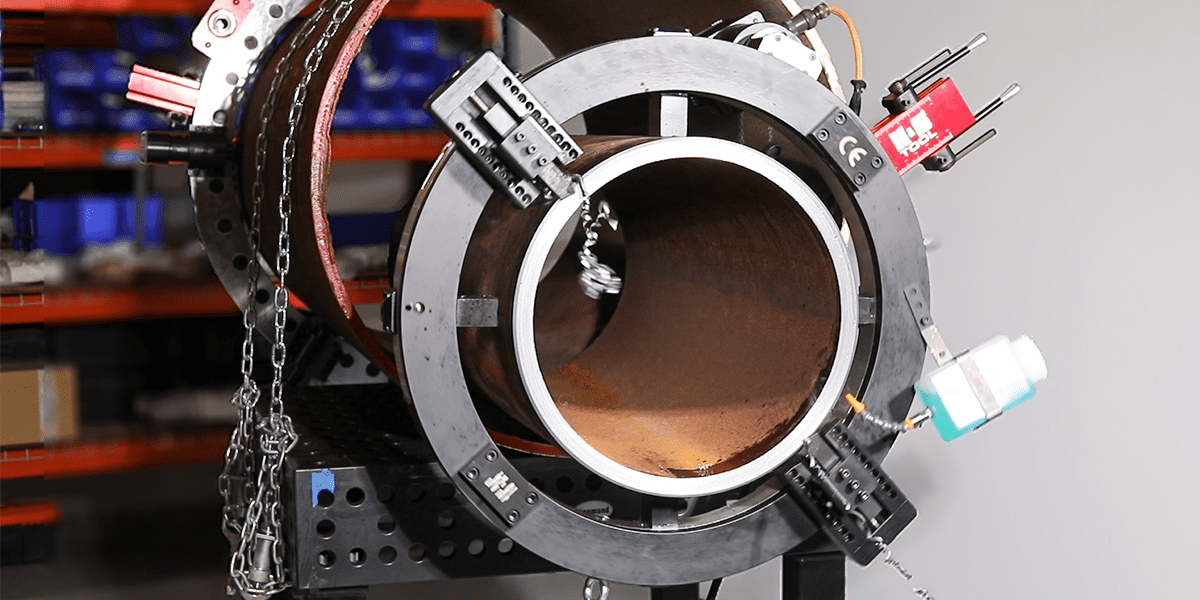

The H&S TOOL Split Frame Clamshell Cold Cutting and Beveling Machine is a versatile, portable lathe designed for precise pipe cutting, Beveling, facing, and counter-boring on pipes from 1″ to 48″ outer diameter. Built to handle a variety of materials, including steel and exotic alloys, this pipe cutting machine features a lightweight aluminum body with a durable steel inner ring gear mounted on solid bearings for enhanced stability. Wide, hardened clamping feet with easy-to-read measurement marks enable fast and repeatable setups, even on out-of-round pipes. With pneumatic, electric, hydraulic, and servo electric power options, the machine adapts seamlessly to diverse job requirements. Adjustable bearings, accessible maintenance points, and customizable H&S TOOL transmission tool slides make this pipe cutting and pipe Beveling machine a flexible, efficient solution for on-site or workshop applications across industries.

Split Frame Clamshell 1 – 48″

RANGE: 1" - 48" OD / 25.4 - 1,220 mm OD

Mobile Nav

HSSFC3 - HSSFC24 (MODULAR BLOCK LOCKING JAWS)

| HSSFC3 | HSSFC6 | HSSFC8 | HSSFC12 | HSSFC16 | HSSFC18 | HSSFC20 | HSSFC24 | |

| Pipe Range OD | 1 – 3″ / 33.4 – 88.9 mm | 1 – 6″ / 33.4 – 168.3 mm | 2 – 8″ / 60.3 – 219.1 mm | 6 – 12″ / 168.3 – 323.9 mm | 10 – 16″ / 273.0 – 406.4 mm | 12 – 18″ / 323.9 – 457.0 mm | 14 – 20″ / 355.6 – 508.0 mm | 18 – 24″ / 457.0 – 610.0 mm |

| Ring Locking Range | 0.98 – 3.62″ / 25 – 92 mm | 0.98 – 7.24″ / 25 – 184 mm | 1.97 – 9.25″ / 50 – 235 mm | 6.50 – 13.78″ / 165 – 350 mm | 10.43 – 16.73″ / 265 – 425 mm | 12.48 – 18.78″ / 317 – 477 mm | 13.50 – 20.79″ / 343 – 528 mm | 17.72 – 25.20″ / 450 – 640 mm |

| Locking Range | 1 – 3″ / 33.4 – 88.9 mm | 1 – 6″ / 33.4 – 168.3 mm | 2 – 8″ / 60.3 – 219.1 mm | 6 – 12″ / 168.3 – 323.9 mm | 10 – 16″ / 273.0 – 406.4 mm | 12 – 18″ / 323.9 – 457.0 mm | 14 – 20″ / 355.6 – 508.0 mm | 18 – 24″ / 457.0 – 610.0 mm |

| Ring Only Weight | 12 kg | 23 kg | 32 kg | 46 kg | 53 kg | 58 kg | 62 kg | 76 kg |

| Toolbox Stroke | 30 mm / 1.18″ | 60 mm / 2.36″ | 60 mm / 2.36″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ |

| Motor Mount Positions | 1 qty | 1 qty | 1 qty | 1 qty | 2 qty | 2 qty | 2 qty | 2 qty |

| Striker Mount Positions | 1 qty | 1 qty | 1 qty | 2 qty | 3 qty | 3 qty | 3 qty | 3 qty |

| Bearing size | S | S | S | S | S | S | S | S |

| Spline Drive Size | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ |

| Pneumatic Idle Speed | 5 – 44 rpm | 5 – 36 rpm | 5 – 28 rpm | 5 – 21 rpm | 5 – 18 rpm | 5 – 17 rpm | 5 – 16 rpm | 5 – 15 rpm |

| Electric Idle Speed | 5 – 40 rpm | 5 – 20 rpm | 5 – 16 rpm | 5 – 12 rpm | n/a | n/a | n/a | n/a |

| Servo Electric Idle Speed | n/a | 1 – 45 rpm | 1 – 36 rpm | 1 – 27 rpm | 1 – 23 rpm | 1 – 21 rpm | 1 – 19 rpm | 1 – 18 rpm |

| Hydraulic Idle Speed | n/a | 5 – 30 rpm | 5 – 28 rpm | 5 – 25 rpm | 5 – 20 rpm | 5 – 19 rpm | 5 – 17 rpm | 5 – 16 rpm |

| Pneumatic Motor Power | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp |

| Double Pneumatic Motor(s) Power | n/a | n/a | n/a | n/a | 3.7 hp | 3.7 hp | 3.7 hp | 3.7 hp |

| Electric Motor Power | 1900 watt | 1900 watt | 1900 watt | 1900 watt | n/a | n/a | n/a | n/a |

| Single Servo Electric Motor Power | n/a | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw |

| Double Servo Electric Motor(s) Power | n/a | n/a | n/a | n/a | 3 Kw | 3 Kw | 3 Kw | 3 Kw |

| Hydraulic Motor Power | n/a | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp |

| Electric / Servo Electric Voltage | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt |

| Electric / Servo Electric Voltage (3 phase) | n/a | n/a | n/a | n/a | 380-480 volt | 380-480 volt | 380-480 volt | 380-480 volt |

| Electric / Servo Electric Frequency | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz |

| Air Working Pressure | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar |

| Air hose Connection | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ |

| Air Consuming Flux (Double x2) | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM |

| Feed Rate per Revolution | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ |

| Locking System | Modular | Modular | Modular | Modular | Modular | Modular | Modular | Modular |

HSSFC30 - HSSFC48 (TELESCOPIC LOCKING JAWS)

| HSSFC30 | HSSFC36 | HSSFC42 | HSSFC48 | |

| Locking Range | 24 – 30″ / 609.6 – 762 mm |

30 – 36″ / 762 – 914.4 mm |

36 – 42″ / 914.4 – 1,066.8 mm |

42 – 48″ / 1,066.8 – 1,219.2 mm |

| Ring Only Weight | 183 kg | 204 kg | 242 kg | 323 kg |

| Toolbox Stroke | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ |

| Motor Mount Positions | 2 qty | 2 qty | 4 qty | 4 qty |

| Striker Mount Positions | 3 qty | 4 qty | 4 qty | 5 qty |

| Bearing size | L | L | L | L |

| Spline Drive Size | 25 mm / 0.98″ | 25 mm / 0.98″ | 25 mm / 0.98″ | 25 mm / 0.98″ |

| Pneumatic Idle Speed | 1 – 8 rpm | 1 – 8 rpm | 1 – 7 rpm | 1 – 6 rpm |

| Electric Idle Speed | n/a | n/a | n/a | n/a |

| Servo Electric Idle Speed | 1 – 9 rpm | 1 – 9 rpm | 1 – 8 rpm | 1 – 7 rpm |

| Hydraulic Idle Speed | 1 – 8 rpm | 1 – 8 rpm | 1 – 8 rpm | 1 – 8 rpm |

| Pneumatic Motor Power | 3.5 hp | 3.5 hp | 3.5 hp | 3.5 hp |

| Double Pneumatic Motor(s) Power | 7 hp | 7 hp | 7 hp | 7 hp |

| Electric Motor Power | n/a | n/a | n/a | n/a |

| Single Servo Electric Motor Power | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw |

| Double Servo Electric Motor(s) Power | 3 Kw | 3 Kw | 3 Kw | 3 Kw |

| Hydraulic Motor Power | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp |

| Electric / Servo Electric Voltage | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt |

| Electric / Servo Electric Voltage (3 phase) | 380-480 volt | 380-480 volt | 380-480 volt | 380-480 volt |

| Electric / Servo Electric Frequency | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz |

| Air Working Pressure | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar |

| Air hose Connection | 3/4″ | 3/4″ | 3/4″ | 3/4″ |

| Air Consuming Flux (Double x2) | 90 cfm / 2500 LPM | 90 cfm / 2500 LPM | 90 cfm / 2500 LPM | 90 cfm / 2500 LPM |

| Feed Rate per Revolution | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ |

| Locking System | Telescopic | Telescopic | Telescopic | Telescopic |

H&S TOOL’s new split-frame clamshells are essentially portable lathes. Offering the versatility to cut and bevel (simultaneously if required), face, counterbore, and o/d machine pipes (and vessels) of almost any diameter. A lightweight aluminium body encases a steel inner ring gear running on solid bearings, ensuring manageability, yet extreme strength and durability. It enables rapid, repeatable concentric setup, even on out-of-round pipes and joints, coupled with wide, hardened clamping feet and easy-to-read rule marks. A range of tooling, power units, and accessories allows you to tailor your machine to your particular job.

Features and Advantages

- 12 models cover a range from 1″ (33.4 mm) to 48″ (1,220 mm) o/d.

- Pneumatic, hydraulic, standard electric, and NC servo electric drive options provide increased versatility.

- Adjustable heavy-duty bearings, combined with easy access maintenance points, allow inspection and adjustment.

- Modular block locking or telescopic locking jaws are effortlessly individually adjusted and allow for quick and easy installation of the clamshell on the pipe. Feet feature easy-read measure marks for rapid setup and adjustment.

- H&S TOOL split frame clamshells accept a wide range of accessories to increase performance and expand machine capabilities.

- Unique ‘H&S TOOL transmission’ tool slides with changeable gears for adjustable radial tool feed.

Product Advantages

-

Advanced Cam Roller Bearing System

Ensures fine adjustment for optimal performance and smooth, precise rotation, reducing maintenance requirements and extending machine life. -

Heavy-Duty Split Frames

Manufactured from high-grade aluminium and treated steel crown, engineered for demanding industrial on-site applications. -

Quick Lock/Unlock Splitting Hinge

Enables rapid setup directly on pipes in situ, saving valuable installation time. -

Protective Custom Case

Supplied in a custom-made metal box with precision foam insert for maximum machine protection (up to HSSFC48). -

Advanced Feeding System

Worm and crown mechanism evenly distributes pressure across the feeding screw, minimizing vibration and tool wear for cleaner, longer-lasting cuts. -

Two-Bolt Motor Mount System

Allows fast motor installation with universal drive block compatibility. Machines from 16″ upwards feature dual mounts, with optional front drive motor mounting. -

Modular Block Jaws

Movable locking system with reinforced external metal plate to relieve stress on the aluminium ring. Compact clamping foot (40 × 60 mm / 1.57 × 2.36″) ensures reliable grip. -

Telescopic Jaws

Enlarged clamping foot (55 × 115 mm / 2.16 × 4.52″) and external mounting provide greater strength and accuracy, ensuring rapid setup and stability. -

Double Striker Feed

Delivers 0.2 mm (0.008″) per revolution, combined with extended engaging handle for hands-free operation. -

Comprehensive Tool Boxes & Accessories

Configurable tool boxes designed to accommodate the full range of H&S tooling. -

Counter Bore Tool Slide

Installs directly after cutting to eliminate internal inconsistencies before welding. Adjustable 0–45° with 150 mm (6″) feed. Optional internal bevel extension offers 20 mm (0.79″) feed for orbital welding prep. -

Outside Bevel Tool Slide

Removes external coatings or reduces pipe OD. Robust 300 mm (11.8″) module with 250 mm (9.85″) functional feed, customized per application. -

Swivel Locking Jaws

Enable pipe offset positioning (1–5° inclination), ideal for elbows, conical surfaces, and offset cuts. -

Flexible Power Options

Available in servo electric, hydraulic, pneumatic, and electric drives. Mounting flanges offered in straight, elbow/right angle, or optional front-drive versions. -

NC Servo Drive Motor System

-

Single Servo System (from HSSCF6): Delta 1.5 kW servo motor with wired remote, for wall thickness up to 25 mm.

-

Double Servo System (from HSSCF16): Two Delta 1.5 kW motors with touchscreen NC control and wireless remote, for >25 mm wall thickness, larger diameters, and exotic materials.

Provides consistent torque under load with superior speed, precision, and safety.

-

-

Precision Tooling Options

-

Formed/Solid HSS-Co tooling: For severing, beveling, double-bevel, compound bevel, J-prep, and counterbore.

-

Holder & Insert tooling: Recommended for efficiency—shared inserts reduce consumable costs.

-

Custom Tooling: Designed to match specialized applications and materials.

-

BROCHURE

OPERATING MANUAL

Related Products